Why we need Wi-Fi 6 technology in inspection robot?

2024.12.31 / By Sailsky

In the context of coal mine working faces

- Inspection robot are particularly important.Coal mine working faces have characteristics such as small space, numerous mechanical equipment, poor visibility, and high temperature. Adequate monitoring is crucial as 80% of safety accidents are due to insufficient monitoring. Manual inspections are long and difficult.

- Wi-Fi 6 technology can enable real-time monitoring in these challenging environments, enhancing safety in coal mining working faces.

Benefits of Wi-Fi 6 intelligent inspection robot

- With the maturity of Wi-Fi 6 technology, its application in smart mines is growing. Using Wi-Fi 6 inspection robot in mines addresses issues such as long distances, high difficulties, and personnel shortages in manual inspections.

- It effectively realizes unmanned fixed positions and less-manned mobile positions, reduces the lag of manual maintenance, and lowers on-site operation risks for personnel. It can provide abnormal data and timely reporting functions to reduce personnel safety hazards.

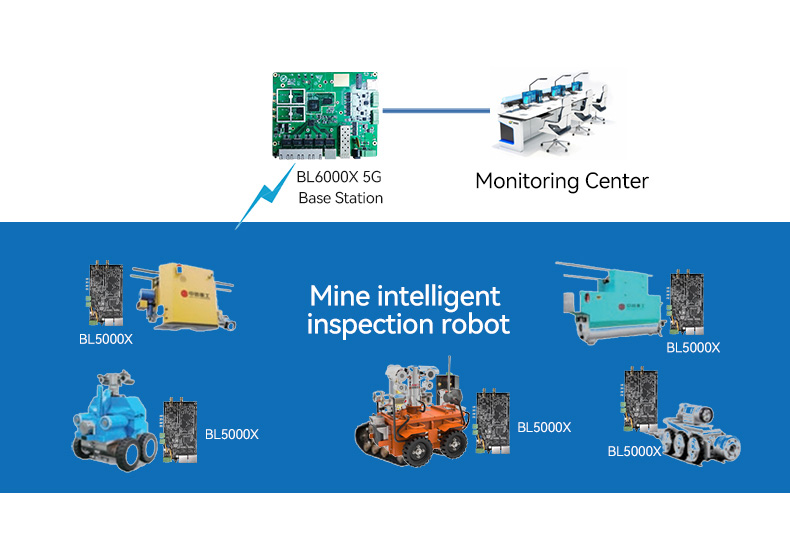

- For example, Sailsky Wi-Fi 6 intelligent inspection robot can operate in manual and automatic modes, equipped with a Wi-Fi 6 module, AI intelligent camera, pickup, smoke sensor, wireless autonomous charger, walking device, etc. It can establish an intelligent inspection monitoring platform based on multi-sensor fusion for various functions.

- Extensive coverage: The mine’s wireless network is large in scale and requires no dead spots for the inspection robot‘s driving route while considering mutual interference among multiple robots. Wi-Fi 6’s improved signal strength and coverage capabilities can meet this need.

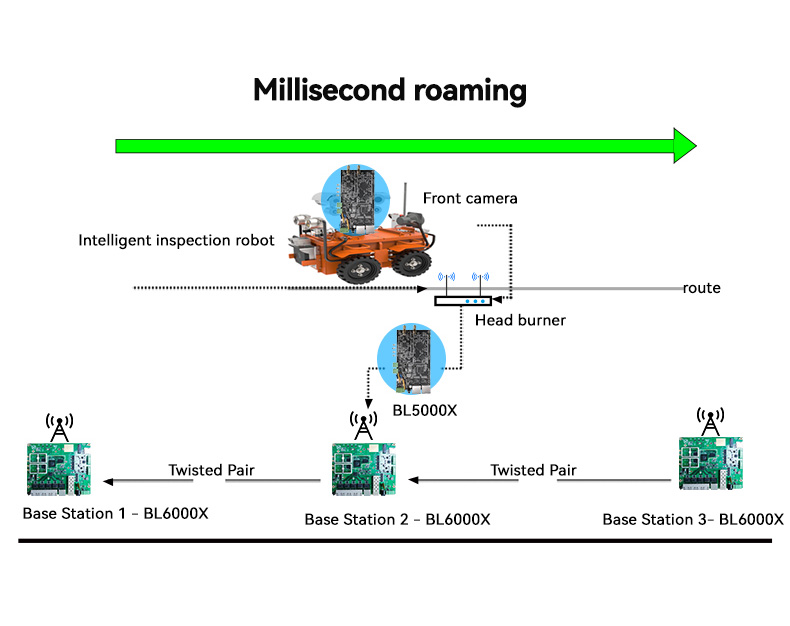

- Millisecond-level roaming: The inspection robot‘s driving process needs fast roaming to ensure low packet loss and latency for a reliable connection. Wi-Fi 6’s advanced roaming capabilities can address this challenge.

- Compact size: The inspection robot‘s internal structure is complex and small, so the wireless terminal needs a compact design. Wi-Fi 6 technology can offer industrial-grade performance in a small size, with high temperature and electromagnetic interference resistance.

- Anti-seismic and anti-aging: The inspection robot‘s vibration and bumps during driving require anti-seismic and anti-aging protection for wireless components. Wi-Fi 6 technology can be designed to withstand these conditions.

- Wireless anti-interference: The mine’s complex environment with dust and high temperature requires higher wireless anti-interference ability. Wi-Fi 6’s advanced features can enhance its resistance to interference.

Sailsky offer BL5000X-Wifi6 AP wireless client which can be built into the inspection robot .

- Up to 3Gbps whole machine rate.

Sailsky BL5000X is a Wi-Fi 6 client following 802.11ax standard. With Qualcomm wifi6 solution architecture, it supports 2.4GHz (2×2) + 5.8GHz (2×2) dual-frequency for simultaneous service, reaching up to 3Gbps. It solves real-time interaction and massive data generation for unmanned vehicles. - Meets intrinsic safety requirements.

Reliable power protection and port protection ensure long-term operation in harsh industrial environments and address high power consumption risks. - Ultra-miniaturized design.

Stable and shock-resistant interface for built-in in inspection robot. - Millisecond-level roaming.

Superior wireless reception, strong anti-interference, and supports millisecond-level seamless fast switching roaming. Used with BL6000X base station for low latency and high bandwidth, suitable for coal mine robot inspection.

Sailsky WiFi 6 Access Point BL5000X intrinsically safe client solves network issues for intelligent inspection robot in mines. Installing these robots realizes real-time monitoring and inspection functions, enhancing safety and management in coal mining. This shows the role and significance of underground intelligent inspection robot.